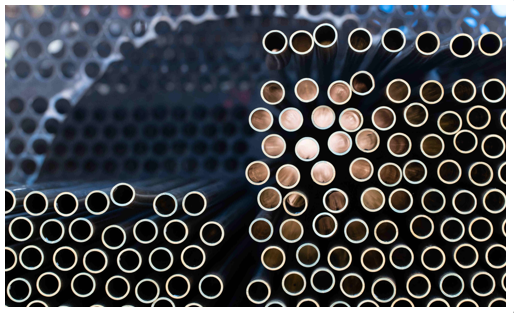

Should an aging heat exchanger be replaced? If so when, and with which new design option?

This study was commissioned to ascertain the business case for re-tubing and to evaluate the life cycle cost benefits of alternative materials.

Using SALVO to determine what interventions are really worthwhile and when

With asset management systems, including risk management, relating to assets with a replacement value of over GBP 40 billion, Scottish Water used SALVO & Decision Support Tools (DST) to make significant savings.

Optimizing shutdown intervals yields significant savings

SABIC Innovative Plastic’s management realised that their shutdown strategy was incurring high costs and downtime losses, and subsequent system instabilities which was compounded by an increasingly competitive market.

What is the optimal inspection interval

for an aging pipeline?

Our clients was at risk of being forced to repair or renew the pipeline at short notice if a leak or pipeline burst were to occur or the corrosion allowance was exceeded.

How frequently should functional testing be carried out on 11kV circuit breakers?

Our client was was seeking to reduce costs whilst maintaining performance and managing risks by optimizing its maintenance strategy.

Optimization of a major shutdown strategy and capital investment practices.

The first pilot studies of component activities (maintenance tasks, spares requirements, problem-solving/root cause analysis) revealed scope for multi-million dollar potential savings or performance improvements.

Sydney Trains finds the best time to renew assets with an innovative process for Life Cycle Optimisation.

By adapting SALVO to establish an innovative cost, risk and performance optimisation process, Sydney Trains have demonstrated individual decision benefits of A$20 + million NPV.

Remote working proves intensive but extraordinarily successful as workshops are forced to abandon.

Challenged to find further efficiencies in the capital programme for end-of-life asset replacements, with a deadline set within less than 2 months, to identify these

efficiencies, this was ambitious planning.

Developing the optimal strategy for rail grinding.

We determined the optimal rail grinding strategy for various curved track sections, representing different wear rates, differential train loading and sections of the lines.

Delivering and demonstrating value-for-money in the management of the asset portfolio.

A major transformation programme to introduce asset management concepts and business processes, including new competencies, culture and tools, simply ‘because it is the right thing to do.’